(5/10)

Cufflinks.

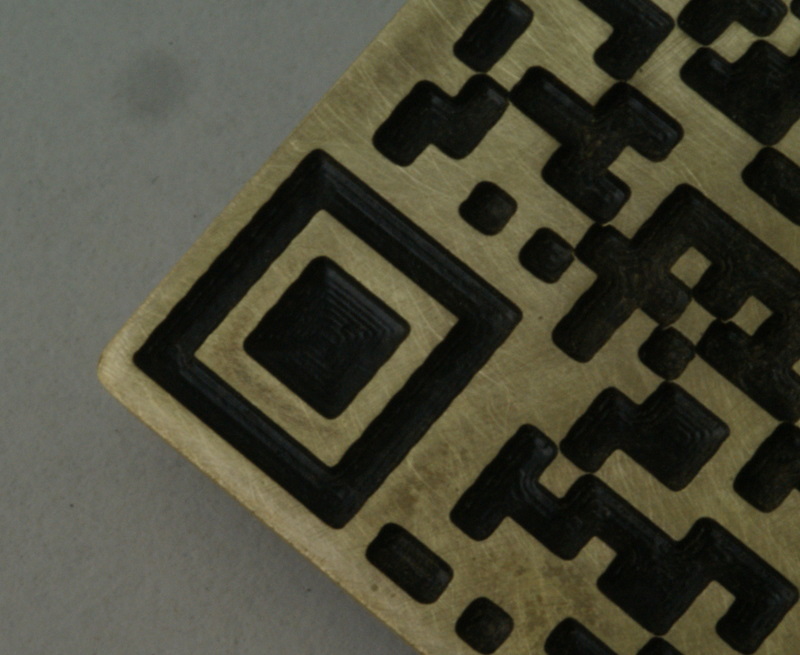

The code is 12.7mm square, with a module size of 0.6mm. It's a version 1 code, the smallest QR possible, so it's 21 modules square. Denso's specs say it should be able to store 20 chars at ECC level M, but I only managed to fit an 18 char URL in on ECC level L. That means I need to use a short URL and a redirect to the real target, which isn't as nice an experience as putting the target URL in the QR code.

Useful QR generators can be found here and here. Denso do define a smaller code, 'Micro QR', but there are few generators and fewer readers for that, so it would be useless in the field.

At this module size, it seems that not all phone cameras will do a reliable decode, because they just won't focus close enough.

Cut from 0.9mm engraving brass (CZ120), using a 0.2mm 36 degree engraving cutter (which actually cuts a 0.4mm groove in my CNC machine) at 8000 rpm, 100 mm/min. Cut depths is 0.3mm.

The black fill is spraypaint (car enamel, in fact), and the brass has been deliberately left matt to get better contrast between brass and paint.

Three badges:

These use the same cutting specs, but are 28mm square with a module size of 1mm, nominal capacity 61 characters.

They are quickly recognised by all the phone cameras I tried them on. And, because they are bigger, I can use the real target URL.

There are a lot of ways to generate the CAD files in CamBam for these. This is the recipe I ended up using, after some experiment:

- Generate the code as a black-and-white PNG, using one of the online generators mentioned above.

- In CamBam, do a Draw / Surface / From Bitmap, at the size you want the finished code to be, leaving the depth at 1mm.

- Then Edit / Surface / Plane Slize Z, with a depth of 0.5. That will generate three slices (at z=0, -0.5, -1).

- Use View / XZ plane to delete the slices at 0 and -1. Delete the surface, too.

- Select all then Edit / Polyline / Arc Fit, with a tolerance of something like 0.001. That simplifies the polyline a lot with no loss of accuracy.

- Select all, then Machining / Pocket. Set Optimisation Mode on the pocket to None, which makes the toolpath generation much quicker at the expense of a small increase in machining time.

Home | Artefacts| Jewellery

Home | Artefacts| Jewellery