9/17

For Derby Mini Maker Faire 2017.

This is an experiment with actuated low-pressure inflated structures, part of some ongoing work with the ever-marvellous Rusty Squid.

First test with the base attached:

Counterweighting is obviously required, this works OK with a 15 kg weight on each of the two back corners. 20 kg might be a better idea.

It's 4.5m long, from back of the base to the tip, and it can reach out 3m to each side of the centerline.

That uses two of the valves (and blower) described below and a PS2 controller running from an Arduino. Code is in github.

There are four pairs of bellows. Each valve is running two pairs (one valve for the tip half of the tentacle, one valve for the base half). The sections in between the bellows are all permanently inflated via one of the tubes running along the bottom.

Here are CAD files for the air valve and the feedback pot arms(the arms need a hinge adding in the other dimension, they do not work well yet)

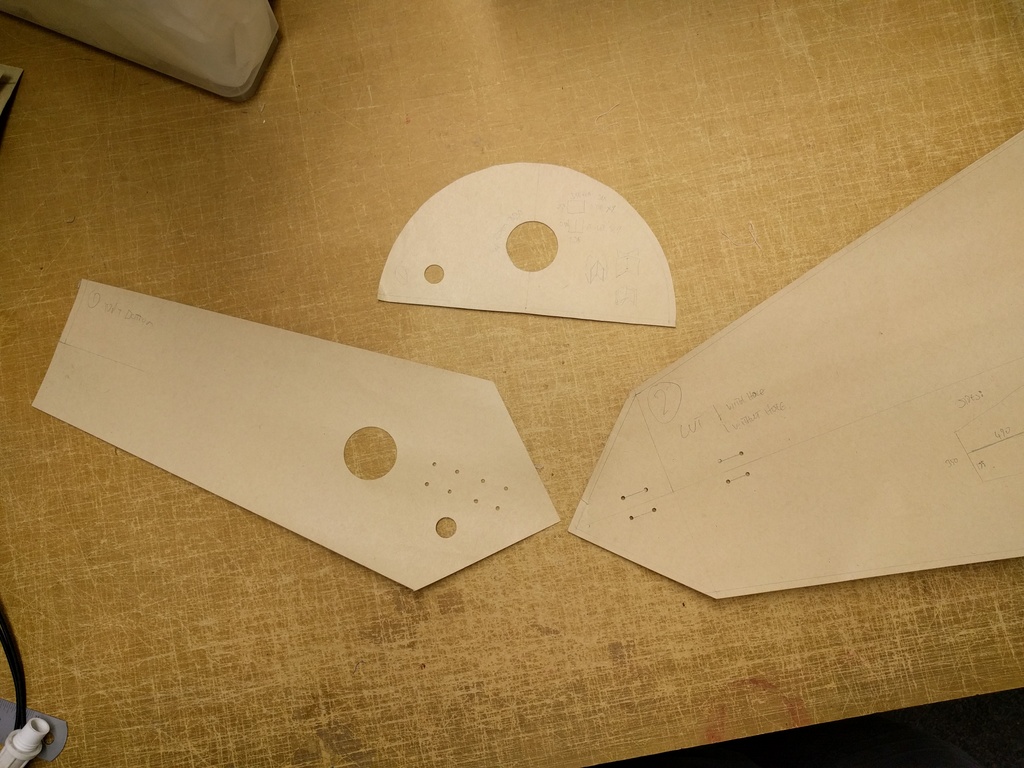

Design was pretty simple, laid out at 1/10 scale on cardboard, and designed as if it was cuboidal. Which it obviously isn't, but it is close enough. The inflation of the flat surfaces does reduce the actuated joint angles, that might be something to address in a V2.

I made card patterns for all the non-simple shapes:

Which turns out to be quite a lot of card

The whole thing packs down quite small:

The plumbing for the air valve is all made from 100mm Manrose ventilation parts from Screwfix and 100mm tumble dryer ducting from eBay. The body of the valve is in a bit of 125mm Manrose ventilation pipe.

Arguably, I should have used 150mm pipe. The valve restricts the flow to less that 1/4 of the area of the pipe at the endplates, and that's probably the most restrictive bit of the system and hence sets the limit on how fast the hinge can move. I coped the 100mm pipes to the side of the 125mm pipe with the aid of an online coping calculator and a printed paper template. And I hand-made a template to layout out the fixing holes and side holes in the 125mm pipe.

Valve assembly-sequence pictures are here, I hope it all makes sense. Feel free to mail me if it doesn't.

And here's the completed 2-valve block:

The blower I used is a cheap 480W bouncy-castle blower from eBay. A smaller blower would probably do, as long as it was designed to run into a stall. There's plenty of spare air supply, so it doesn't matter if the sewing is a bit leaky.

The fabric I used was a cheap 4oz PU coated nylon which seemed to work very well.

For the sake of history, here's the first test joint:

Running a quick test:

Home | Artefacts| Robots

Home | Artefacts| Robots