(3/12)

For steampunk purposes, for the Waltz on the Wye 2012

Brass & ebony.

Parts:

The movement is a skeleton Chinese 6497/6498 style from eBay seller

777watchpartsusa.

It was about £40 or so. To find more like it, search eBay for

"skeleton 6497 movement".

It's worth looking at both ebay.co.uk and ebay.com.

For comparison with a real ETA-made one, take a look at Otto Frei.

Hands are 6497-compatible from Rouhelena

Watch glasses are 40 x 1mm double-dome from Cousins

Materials:

The body is machined from ebony from Dictum. The ebony was a dream to machine, dense and strong.

Top & bottom plates are machined from 0.9mm CZ120 engraving brass.

Bolts & nuts are steel M2 high-head, I think from Polly Model Engineering

Hanger and winder are machined from some of my grandfather's collection of offcuts of brass rod. Alloy unknown, but I'm sure is is no newer than the 50s.

Chain is fabricated from brazing rod, rolled square, then silver-solvered.

All the brass parts have given an hour in ammonia-damp sawdust then repolished to give them a spurious patina of age.

The ebony has been finished with fine wet & dry paper, then waxed.

All the CAD & CAM was done with the invaluable CamBam. Here's the CamBam file and the GCode.

The most nerve-wracking part was fitting the hands to the movement. I used a cheap Presto-style watch hand presser from eBay, which has a vertical plunger, and even with that it was hard to know how hard to push and exactly when the parts were all aligned correctly.

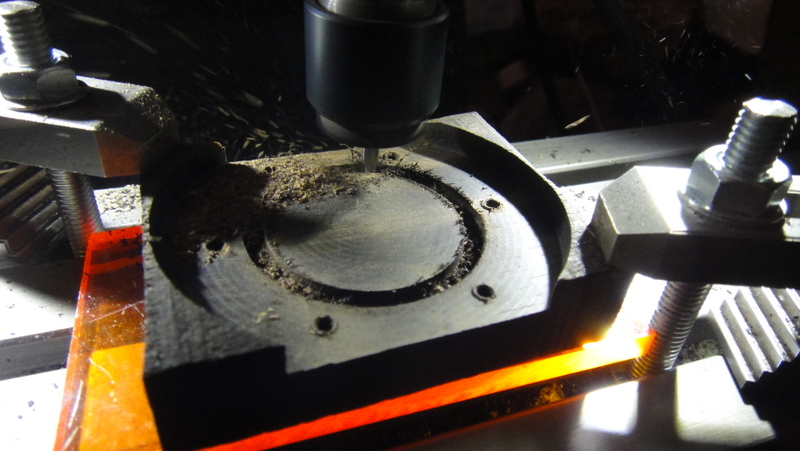

Machining the ebony:

The body was held in a machined recess in a bit of acrylic while the back bores were cut:

Machining the winder bores:

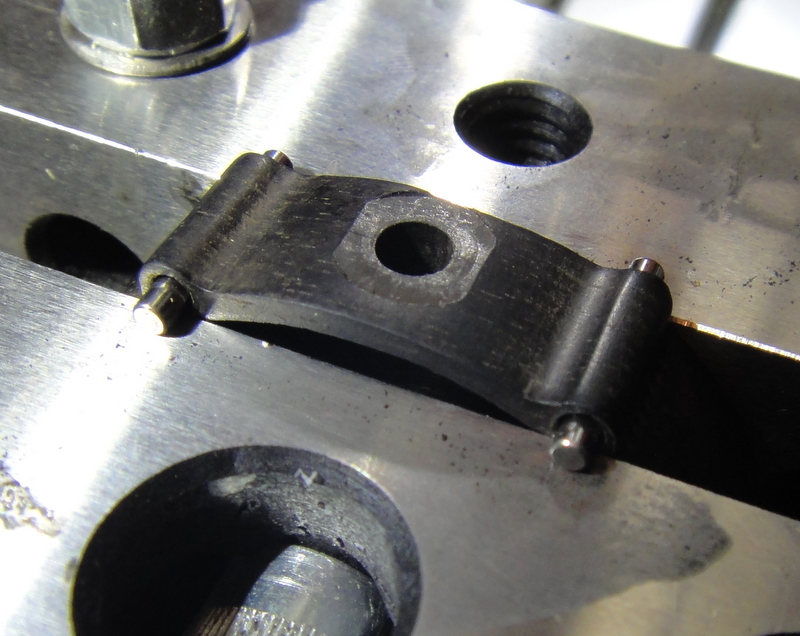

Hanger parts, turned on the lathe, and a fabricated loop:

Hanger epoxied into the body:

Ready for assembly:

See the tiny silver screw at the top? To remove the crown shaft, unscrew that by half a turn. Perhaps three quarters. No more. Otherwise (apparently) a lot of parts fall out.

Once that is unscrewed, the crown shaft pulls out. This tiny cog is also then loose, and will fall out when you turn the movement over:

Winder, turned & filed to a ball in the lathe, then drilled out to 1mm:

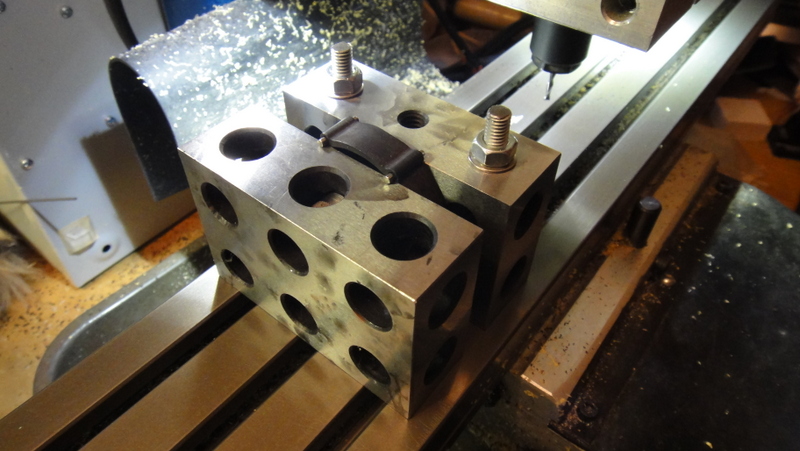

Milling the winder flutes:

Tapping the winder, with a 1.2mm tap from Cousins

Finished:

Home | Artefacts| CNC

Home | Artefacts| CNC